When power fails, lighting inverters are the unsung heroes that keep pathways illuminated, life safe, and buildings code-compliant. In this post, we’ll explain what lighting inverters are, why they matter, key design considerations, and how Myers inverter offerings serve this mission.

What Is a Lighting Inverter?

A lighting inverter (sometimes called an emergency lighting inverter or inverter power system) is a backup power device that takes stored energy (usually from batteries) and converts it to AC power to feed lighting fixtures during a power interruption. Unlike full UPS systems that support broad loads, lighting inverters are specifically sized and engineered to support lighting (especially path-of-egress or exit/emergency lighting) and sometimes associated critical loads.

In practice, the inverter “bridges” the gap when mains power fails, ensuring that emergency lighting circuits remain powered for the required duration (often 90 minutes or more under building codes).

Key features of modern lighting inverters include:

- High efficiency (to reduce losses)

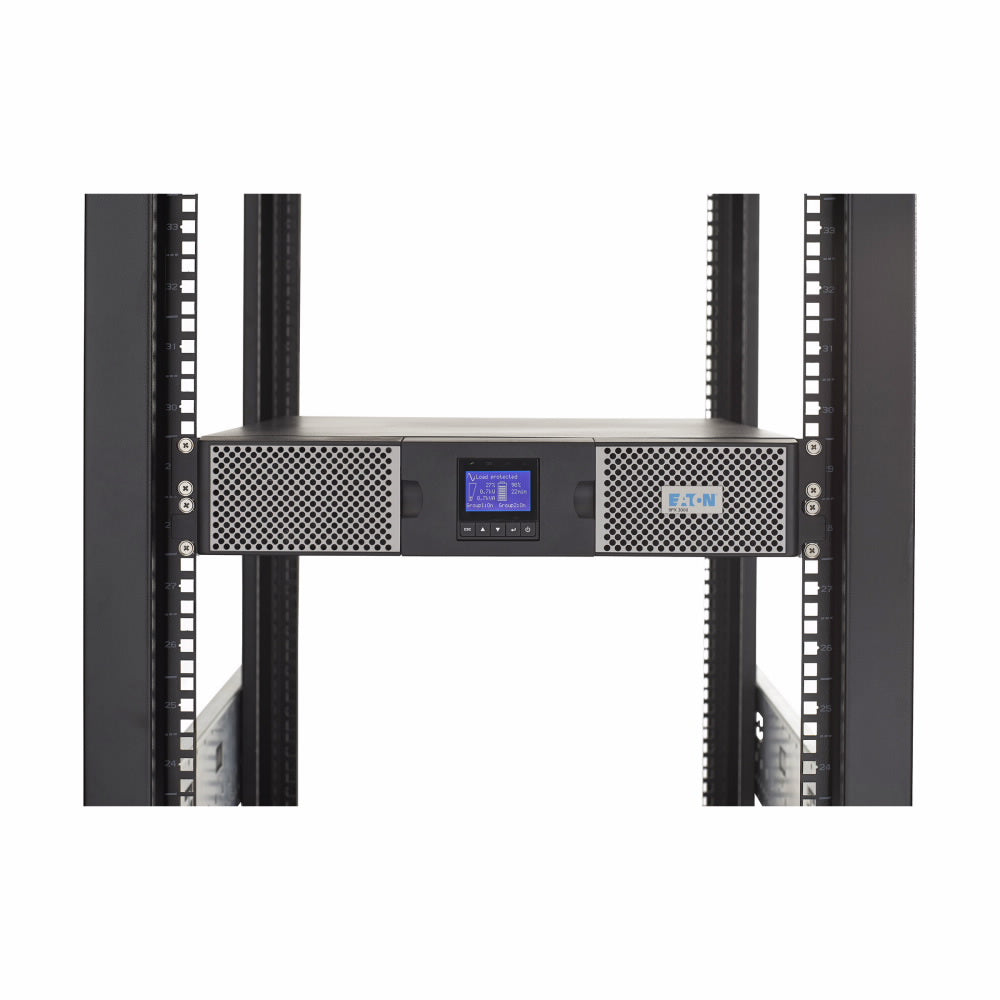

- Compact / modular design (to fit in constrained electrical rooms)

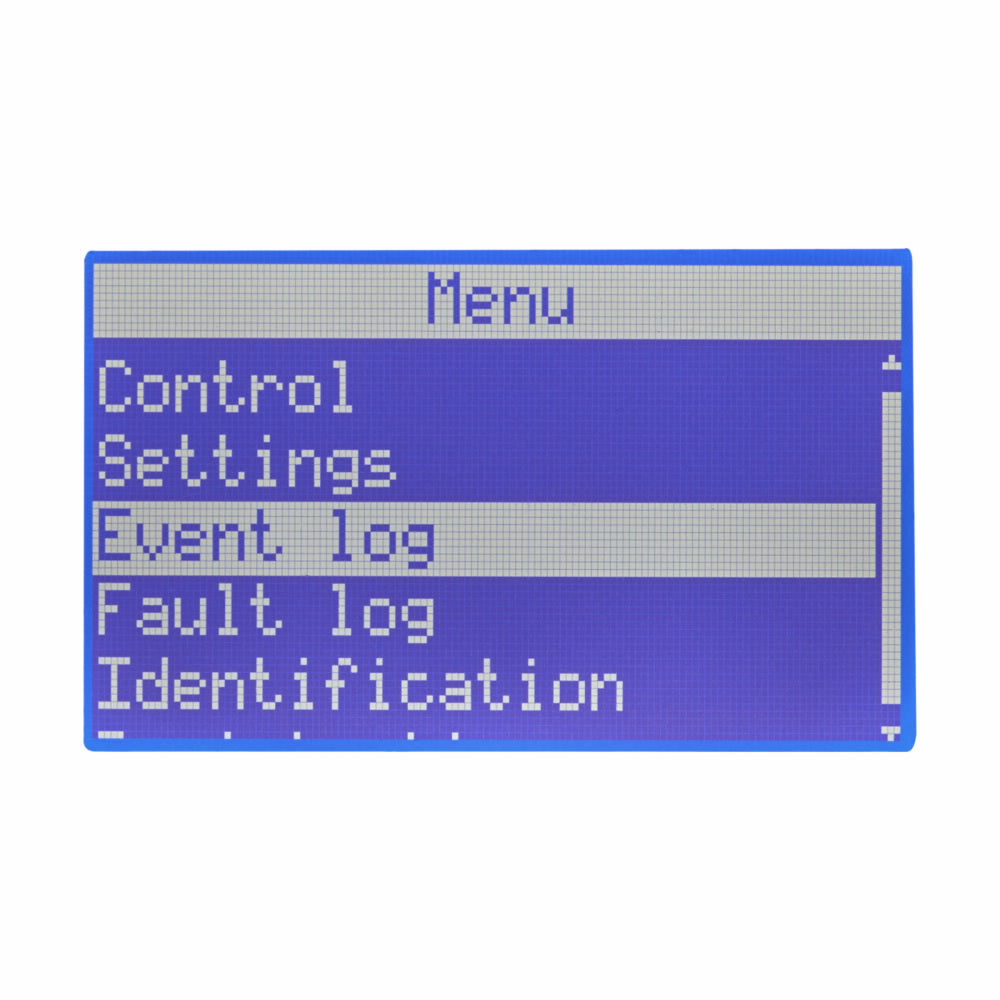

- Communications / monitoring (to alert facility staff, integrate in building systems)

- Scalable capacity (to match load and growth)

Why Lighting Inverters Matter in Life Safety & Code Compliance

Safety: In an emergency (fire, blackout, grid failure), occupants need safe, illuminated paths to exits. Lighting inverters help maintain illumination when the grid fails.

Code and regulation: Many building codes (e.g. NFPA, local jurisdictions) require emergency lighting to remain on for a specified time (often 90 minutes). The design of inverter systems must satisfy those requirements.

Reliability: A well-designed lighting inverter is more reliable (less prone to failure) than ad hoc battery setups because of built-in diagnostics, monitoring, and redundancy options.

Economy & efficiency: Modern inverters reduce waste (heat, losses) relative to older legacy systems, and modular designs can reduce initial and lifecycle cost.

Key Design Considerations for Lighting Inverters

When choosing a lighting inverter, it’s important to evaluate several factors that will affect performance, compliance, and long-term reliability.

Load sizing and diversity should be the first step. The inverter needs to be properly sized to support all connected lighting loads, including any surge or motor demands. It’s also important to account for the type of fixtures—such as HID versus LED—and leave enough headroom for future expansion.

Next, consider battery sizing and duration. Most codes require at least 90 minutes of runtime during an outage, so batteries must be sized to handle the worst-case load. Temperature conditions and derating factors also play a role here, and allowing a maintenance margin ensures continued compliance over time.

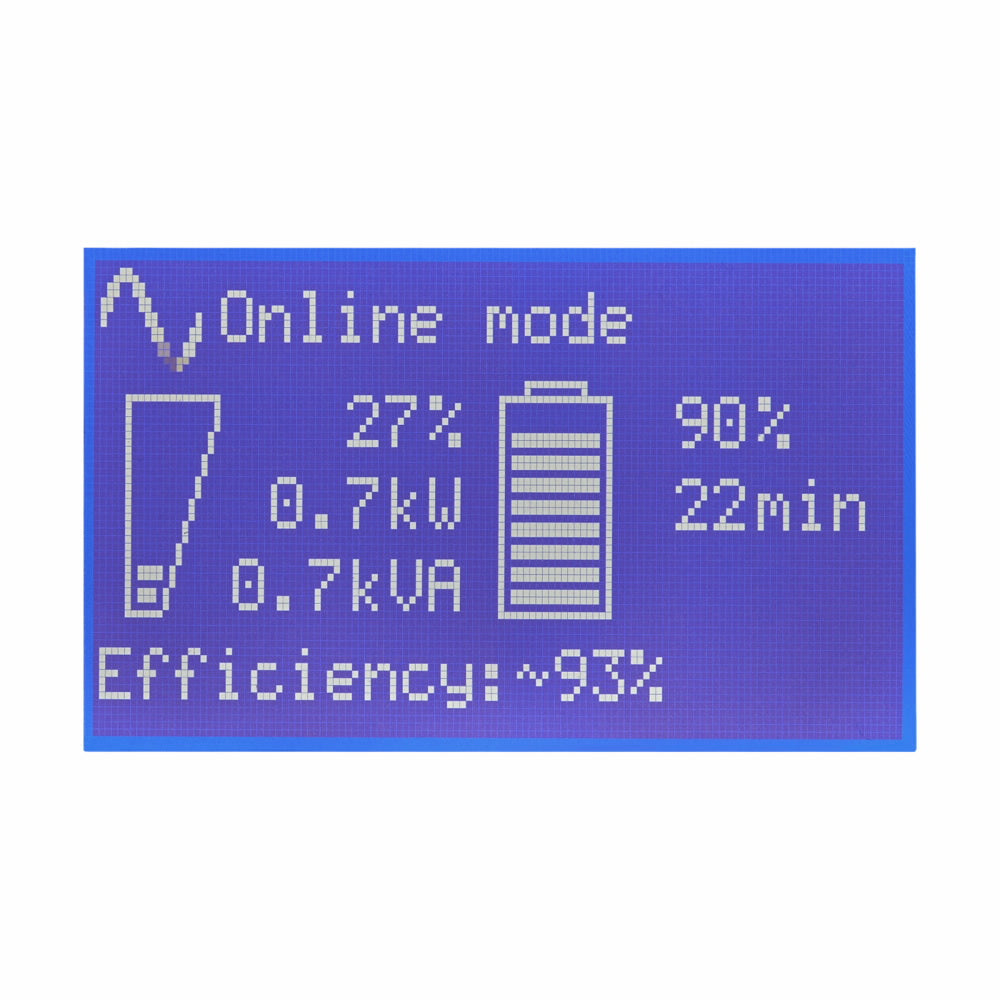

Efficiency and power losses matter too. Inefficient systems waste energy, produce excess heat, and may require more robust cooling. A high-efficiency inverter with low idle losses not only reduces energy costs but also eases strain on the facility’s infrastructure.

Because space is often at a premium, footprint and modularity are critical. Many electrical rooms have limited capacity, so a compact or modular inverter design can make installation easier and provide flexibility for scaling later.

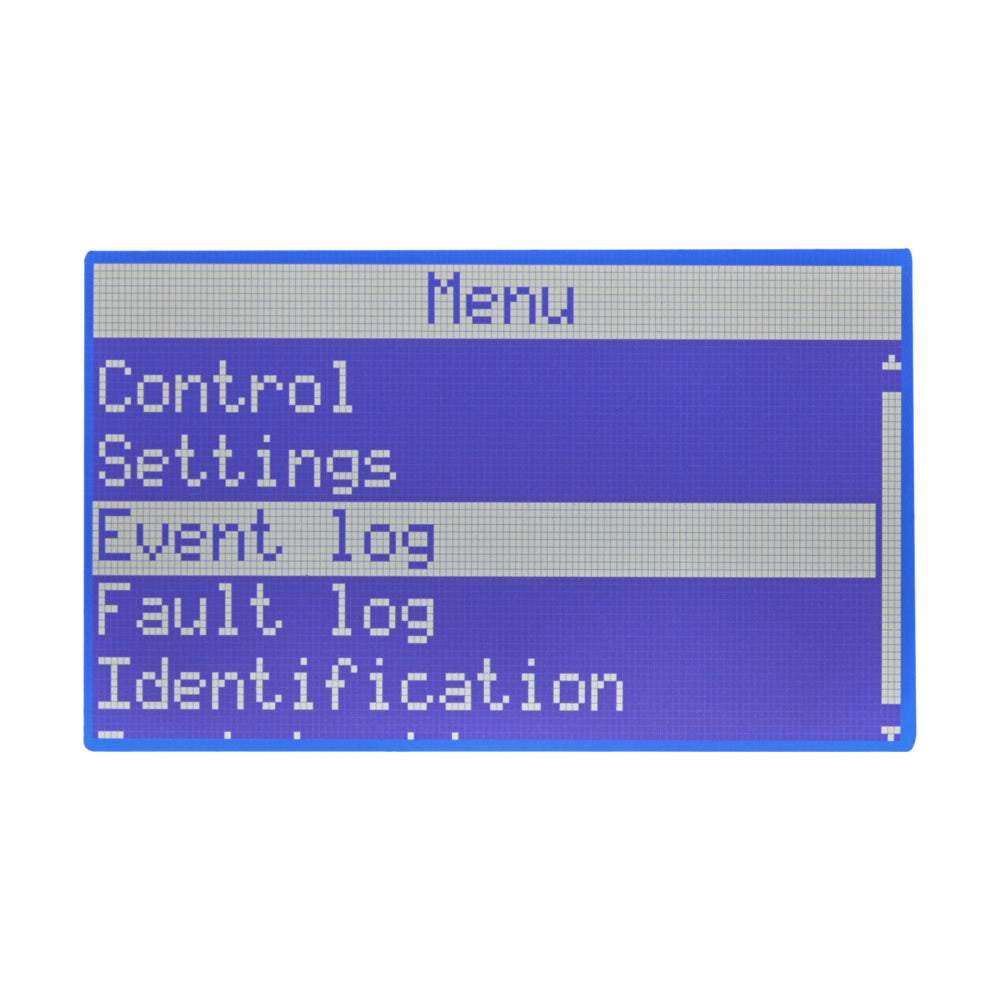

Modern facilities also benefit from communications and monitoring capabilities. Look for systems that integrate with building management platforms via BACnet, Modbus, or IoT connectivity. These features provide real-time oversight, fault alerts, and data logging that improve reliability.

In high-stakes environments, redundancy and scalability are essential. Systems that allow modules to run in parallel or in an N+1 configuration ensure uninterrupted operation even if one module is offline for service or failure.

Finally, don’t overlook environmental and code requirements. Depending on your building type and location, you may need systems with UL listings, seismic (OSHPD) ratings, or other certifications to meet local regulations.

By weighing these considerations carefully, facility managers and engineers can select a lighting inverter that not only meets compliance requirements but also delivers reliability, efficiency, and room for growth.

Spotlight: Myers Lighting Inverter Portfolio

- Myers offers a broad lineup of inverter systems tailored to lighting needs across many applications.

- Wide capacity range: Their inverters span from small micro and mini units (25 VA up to a few kVA) to large three-phase systems (up to 60 kVA/60 kW)

- Single-phase & three-phase options: For small to large applications, including industrial loads

- Compact and modular designs: Many inverter models come in modular battery cabinet form, allowing fitting into tight electrical rooms

- High connectivity & monitoring: Support of BACnet MS/TP, BACnet TCP/IP, Modbus RTU/TCP, and cloud-based IoT Inverter Connect for remote diagnostics and oversight

- Specialized models: Outdoor/remote inverters (e.g. “Illuminator SR, CR, DR”) and seismic rated units (OSHPD) for jurisdictions requiring special design certifications

Implementation Tips & Best Practices

- Undertake a detailed lighting load survey: Inventory all fixtures on emergency circuits, categorize LED vs HID, consider future expansions, and allow margin for growth.

- Temperature & battery derating: Batteries lose capacity at higher ambient temperatures. Always derate per manufacturer guidance and consider environment controls.

- Plan for periodic testing & maintenance: Inverters and batteries require monthly/quarterly/annual testing. Ensure space and access for servicing.

- Integrate with building management systems: Use the inverter’s communication features to feed alarms, fault logs, status to BMS or facility dashboards.

- Redundancy where critical: In high-stakes environments (data centers, healthcare), use parallel modules or even dual systems to maintain uptime during maintenance or failure.

- Select the right warranty and service contract: A quality service plan helps ensure the inverter system performs as intended over its lifecycle.

At CP Warehouse, we know lighting inverters are essential for life safety and regulatory compliance. Their role is often behind the scenes, but in an emergency, they become indispensable. Myers inverter portfolio offers solutions from micro to large-scale, with connectivity and features that meet modern facility expectations.

Having the right emergency lighting inverter solution is critical for your facility. Our team is here to help—contact us today and we’ll ensure you have the solution that keeps your facility prepared and safe.